Method of functioning

Two rotating and separate gears are found in Gear pumps along with intermeshing teeth. As these are separated meshed teeth, it produces a partial vacuum that is stocked by the fluid that is being pumped. The fluid gets trapped as the gears keep on rotating and is passed just about the casing to the pump’s discharge side. The fluid is then re-meshed by the gear teeth that produce the pumping action. Numerous kinds of pump designs are available but in the end these employ the similar pumping principle. Pumps never get stuck. The preliminary pressure of fluid can be atmospheric that depends largely upon the structure.

The industrial applications

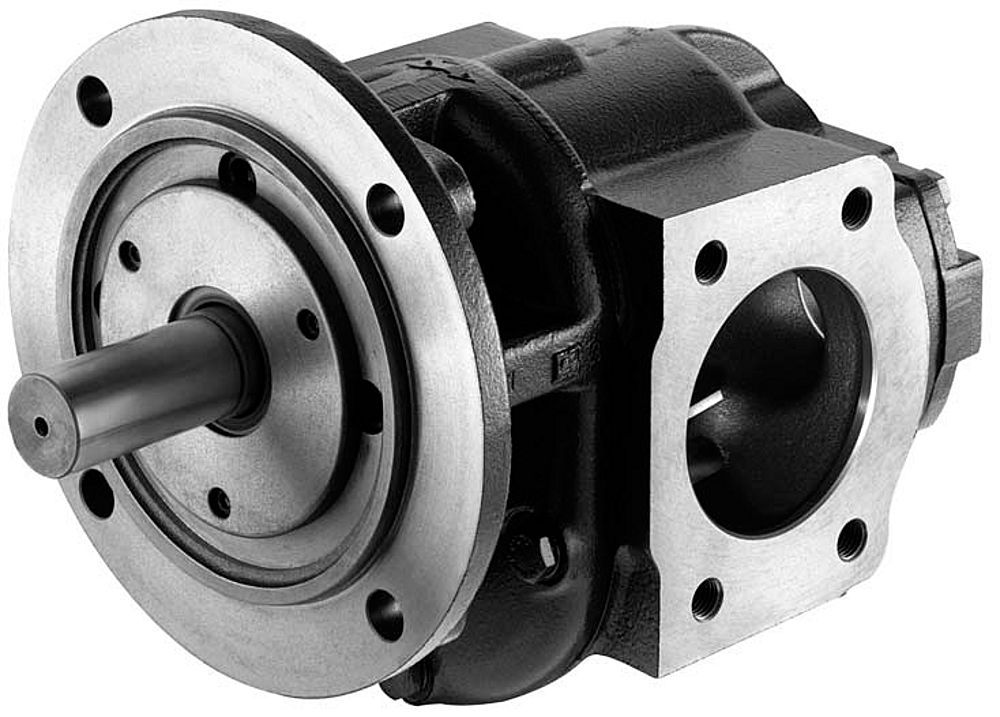

Two major variations of Gear pumps can be found that are external and internal gear pumps. The former utilizes two external gears, and the latter uses an external and an internal spur gear. Apart from this Gerotor pumps also is regarded as a type of gear pump. The industries that mainly utilize these pumps are petrochemical, chemicals, ink and paint, adhesives and resins, paper and pulp, food. Few important applications include pitch, crude oil, pure bitumen, diesel oil, acids, mixed chemicals, soap, latex, black liquor, sludge, molasses and many more. However, make sure you are obtaining the products from a firm that has a well-thought-of name in this industry.

Marking the advantages

Several benefits can be found when Gear pumps are concerned. Firstly, these are capable of moving easily viscous fluids. Secondly, the pumping action of this kind of pump is finite that makes the production controllable. Thirdly, gear pumps are made self-priming by the actions. Fourthly, BEP or Best Efficiency Point cannot be attached to pumps as mentioned earlier. Fifthly, these are even regarded as biorational. Visit the official websites of the companies selling the products for learning more details about the products.